What is a dieline and why is it important in packaging design?

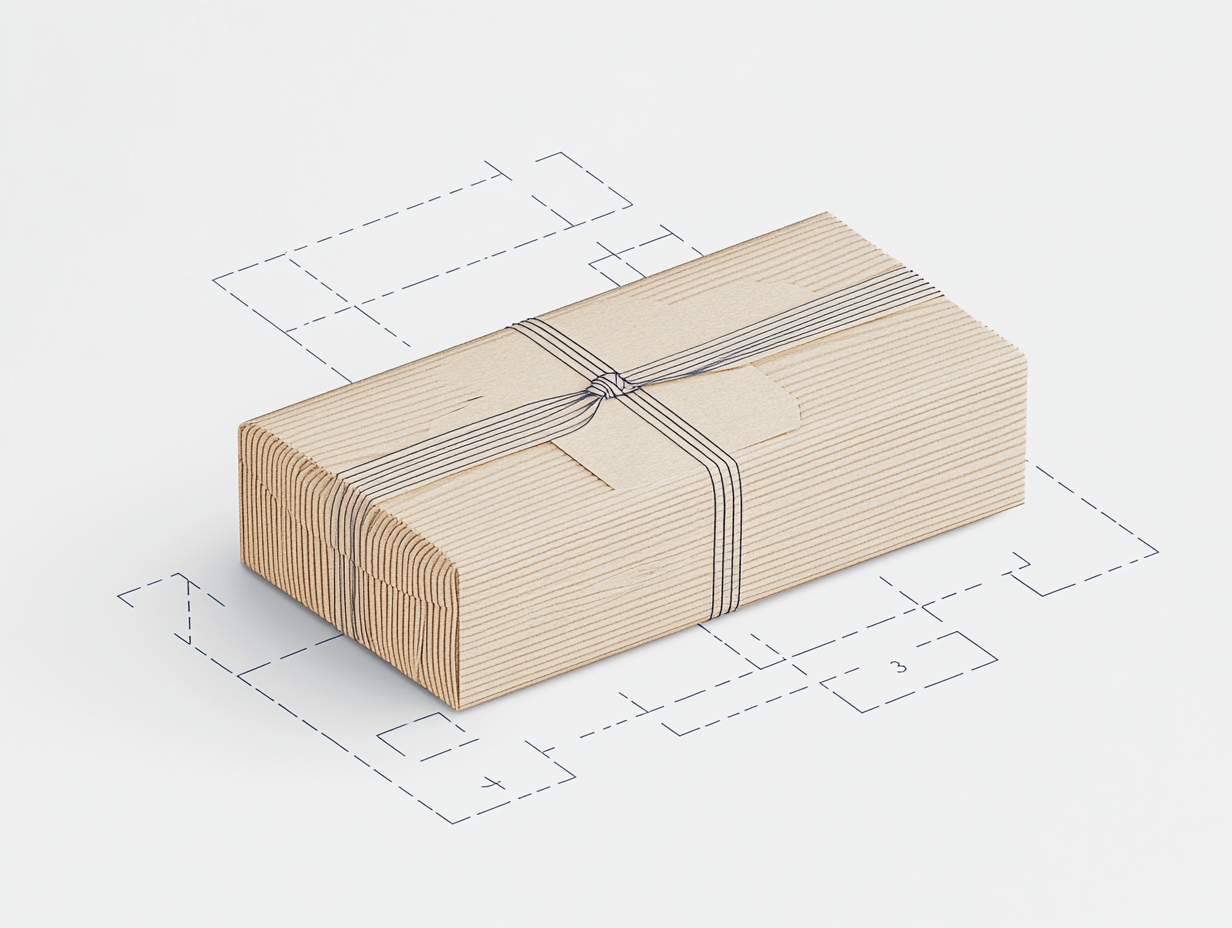

In packaging design, turning a digital idea into a real product uses specific plans known as dielines. These vector art designs show a clear 2D layout, which includes the exact size needed for production. This layout helps with cutting, folding, and putting together the final product. Knowing about dielines and using software like Artioscad is important for graphic designers who create the artwork. It is also vital for printers who make these designs a reality.

The Role of Die-Lines in Packaging Design

Imagine opening a cereal box so it lies flat. You will see lines showing where to cut, fold, and glue the square packages. These lines are called dielines. They are essential to packaging design. They change a flat piece of material into a useful and attractive package.

A dieline is very important for communication. It helps designers, clients, and manufacturers work together. This tool reduces confusion and lowers the chances of mistakes in production. It makes sure the final product matches the original idea.

Defining a Die-Line and Its Importance

A dieline is a flat, two-dimensional diagram that shows how a package will be folded and glued. A packaging designer creates it to serve as a template for making custom packaging, including various type of packaging. The dieline includes important markings like cut lines, fold lines, glue tabs, and bleed allowances as well as detailed lines of a package. This information helps with the die-cutting and printing processes.

Having a good dieline is very important. It makes sure that the final product is strong and works well. It also shows where to place visual elements like logos, text, and illustrations for the greatest effect.

In addition, an accurate dieline makes the production process easier for inexperienced designers. This saves time and resources. It helps avoid mistakes during manufacturing, ensuring that the final product matches the specifications and quality that the designer and client require.

The Impact of Die-Lines on Product Integrity and Visual Appeal

Dielines are very important for keeping products safe. A well-made dieline helps the food packaging hold fragile items or groups of components during shipping and handling. It makes sure that all the flaps, tabs, and panels fit together well, creating a strong structure.

Dielines also affect how the final product looks, particularly in regards to the physical elements of the final printed product. The exact placement of visual elements, like logos, text, and graphics, depends on having a correct dieline. It decides where these elements go in relation to folds and cuts, making sure they stand out and are not hidden by the packaging itself.

Also, a clear dieline can help reduce the risk of unforeseen errors in the production of many types of packages. Mistakes in cut lines or fold lines can ruin the look of the packaging. These errors can lead to misaligned graphics or skewed text, which might harm how people see the brand.

Key Elements of a Die-Line for Packaging

To understand dielines, it’s important to learn about their key parts. These parts work together to make packaging strong, nice to look at, and useful. Knowing what each part does is important for both designers and printers.

Cut lines show where to separate the package from the extra material. Fold lines show how the package will look in the end. Each part has a special job. Extra markings, like glue tabs, perforation lines, and bleed allowances, help make the production process easier and more accurate.

Understanding Folds, Cuts, and Tabs

At the center of a dieline are cut lines, fold lines, and glue tabs. These markings are key for the structure of any package design. They help change a flat sheet into a 3D shape. It is important to know how they are different.

Cut lines are solid lines that show where to cut the packaging material. They define the outer edges of the package and any cutouts inside it. In contrast, fold lines are shown as dashed or dotted lines. They show where the material needs to bend. These lines create the creases that allow the package to fold correctly.

Glue tabs are small flaps with slanted edges. They are placed in certain spots to connect different parts of the package. Glue tabs help ensure the package closes securely and keeps its strength. These parts may seem simple, but they are essential to any good dieline design.

Choosing the Right Die-Line for Your Product

Selecting the appropriate dieline is vital for ensuring the final packaging effectively houses and showcases the product. Factors like the product’s dimensions, fragility, and the desired visual aesthetics all come into play when determining the ideal dieline.

To accommodate the vast array of products, various dieline styles have been developed over time. Each style offers a unique set of structural and aesthetic qualities. Therefore, understanding the nuances of each dieline type is essential for making an informed decision.

For instance, a simple tuck-end box might be perfect for lightweight items, while a more robust mailer box with interlocking flaps could be better suited for fragile goods. Ultimately, the choice depends on striking the perfect balance between functionality and visual appeal.

| Dieline Type | Description | Applications |

| Regular Slotted Carton | Most common type, easy to assemble, cost-effective | Shipping boxes, storage boxes |

| Tuck End Box | Easy to open and close, provides a clean look | Retail packaging, cosmetic boxes, gift boxes |

| Mailer Box | Durable, secure closure, ideal for shipping | Subscription boxes, e-commerce packaging |

| Display Box | Designed for retail shelf display, often with a window to showcase the product | Cosmetics, electronics, food products |

Technical Terms Every Designer Should Know

While cuts, folds, and tabs are important, other technical terms also impact how good a dieline is. These words relate to printing and packaging processes. They help make sure the final product matches the design well.

Safety lines, bleeds, and registration marks are some of these key elements. Knowing their importance helps designers make files that are ready for print. This knowledge can reduce mistakes during production.

Rolls, Seams, and Their Significance in Packaging

The printing industry uses exact words to give clear instructions. Words like “rolls” and “seams” may sound simple, but they have specific meanings in packaging design. These meanings are important for a smooth production process.

Rolls show how paper or cardboard is fed into the printing press. This affects the grain’s direction, which changes how flexible the material is and how it folds. Not paying attention to the grain direction can cause cracks on folds. This can make the final product less sturdy, especially for items like pocket folders or those with complex folds.

Seams are where two edges of packaging material come together. They are important for making boxes and other packages strong. The way creases are placed and what kind of glue is used for seams can greatly affect the package’s strength, durability, and look.

The Concept of Bleeds in Design Placement

Bleed lines are an important part of dielines. They help make sure that printed colors and designs reach the edge of the packaging after it is cut. These lines are drawn in the dieline and show where the extra space for printing is. This extra space is removed when the package is made. The “bleed” helps fix small mistakes that can happen when cutting, so there are no white edges on the final product.

For example, if you create a bright and colorful design for a cereal box, missing bleed lines can cause even a small error during cutting to show white cardboard along the edges. This would ruin the design. Using bleed lines helps avoid this problem and keeps the look nice and professional.

Along with bleed lines, safety lines are also important. They serve as a visual guide in the dieline to keep any important parts of the design from getting cut off. Safety lines mark a safe zone where text, logos, and images should stay. Following these safety rules is especially key when the packaging is in its flattened form. This way, we can prevent any unexpected cut-offs during the cutting process.

Conclusion

Understanding dielines is very important for packaging designers. It helps keep the product safe and looking good. By knowing folds, cuts, and tabs, designers can pick the right dieline for their item. Knowing terms like rolls, seams, and bleeds helps make designs more precise. Learning these ideas improves the quality of packaging design and represents the brand better. If you want expert help with dielines and packaging design, reach out to us today.